This range of torsional couplings solve torsional vibration problems typical of those found in diesel engine driven equipment applications.

The torsional coupling dampens torsional vibrations and tunes the system to have critical speeds outside the operating range.

jbj Techniques Ltd can analyse the application and determine the exact torsional coupling needed for almost any application.

LF torsional couplings

Substantial shock, vibration and misalignment capabilities, maintenance free, fail-safe operation.

Characteristics and benefits of LF Torsional Couplings

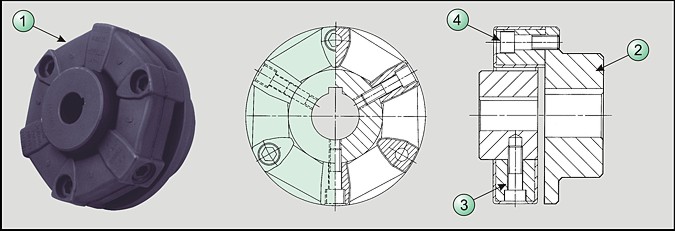

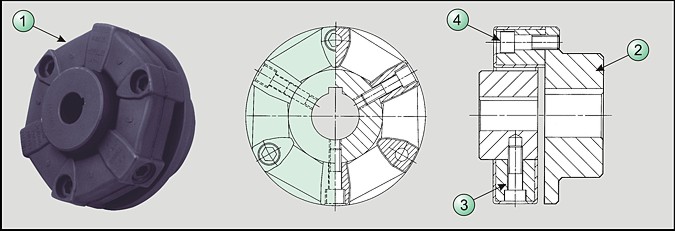

The basic component of the LF torsional coupling available from jbj Techniques is the unique and highly versatile elastomeric element (1). This element can be easily mounted in a number of different ways depending on the application, and without special design changes or complex hardware modifications. The element, which is available in different materials for optimum performance, is connected to a cylindrical hub (2) with radial screws (3) and then to a flanged hub by axial (4) screws. This unique coupling design is remarkably simple, highly effective, and gives the LF torsional coupling unmatched performance capabilities.

Exceptional Features

1) Free end float (Type S).

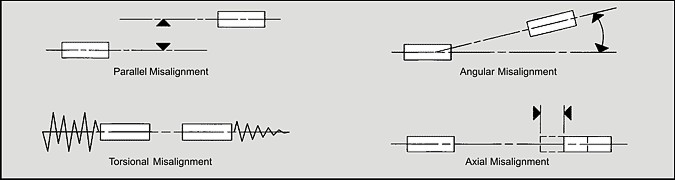

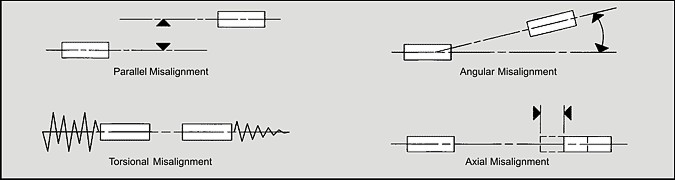

2) Substantial shock, vibration and misalignment capabilities.

3) Fail-safe operation.

4) Coupling allows “blind” connection of equipment.

5) High-speed capabilities.

6) Economic design.

7) Application versatility.

8) Low weight, low moment of inertia.

9) Free from noise and electrically insulating.

10) No lubrication, maintenance free.

11) Oil, heat and corrosion resistant elements (Hytrel®, Zytel®).

12) Easy to disconnect driver and driven without moving equipment or coupling hubs.

13) Unique “air flow” design assists in keeping components cool during operation.

14) Short profile for tight engine housing, or shaft-to-shaft requirements.

15) Easily assembled, no special bands, tools or time consuming assembly procedures.

16) Professional application assistance and expertise worldwide.

17) Torque transmission does not exert harmful reaction loads on equipment.

18) Various element materials for variation in torsional stiffness and environmental resistance.

LF Torsional Coupling System

There are six standard LF Torsional coupling models. The simple, unique design of the LF Torsional coupling permits this wide range of models, from common components, to meet each application requirement. From engine flywheel housing or the long corrosive span of a cooling tower, we have the optimum LF Torsional coupling model available for your application.

Please see page 3 of the catalogue for further information:

www.jbj.co.uk/e-publications/Torsional-couplings-from-jbj_Techniques_Limited/3/index.html

Assistance to select the correct coupling

If you would like assistance in selecting the correct model and size coupling for your application please fill in the form on page 7 of

www.jbj.co.uk/e-publications/Torsional-couplings-from-jbj_Techniques_Limited/7/index.html by downloading it, completing it and email or fax to the jbj Techniques technical office email: info@jbj.co.uk or fax: 01737 772041 and we will contact you as soon as possible with recommendations for the right coupling for you mechanical power transmission application. Thank you.

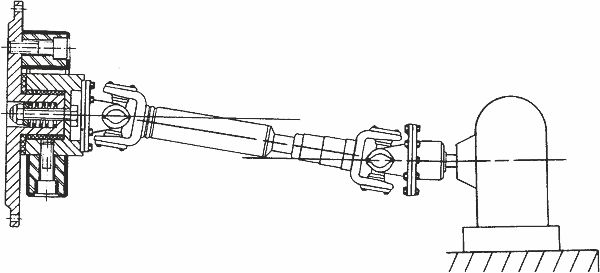

Damper Couplings

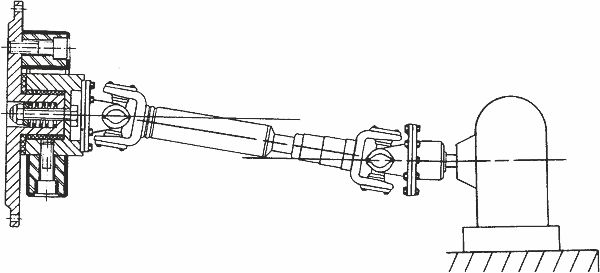

The damper coupling (sometimes referrred to as the intermediate coupling) is used with universal joint (U-joint) and Cardan shafts to eliminate torsional vibrations from the diesel engine being transmitted to the driven equipment.

The damper coupling assures that the drive systems are free of dangerous resonance speeds in the operating speed range and eliminates damage to gears, bearings, seals and spline fretting the driven equipment.

LK Torsional Coupling System

Salient features and advantages

» Compact, light, robust and safe in operation with a long service life.

» Oil resistant and suitable for temperatures of -40°C up to +150°C.

» High torsional stiffness allowing operation below critical speed without resonances, provided it is correctly selected.

» Service free combination of sintered metal with highly shock resistant, temperature stabilized special polyamide.

» Short mounting length, easy assembly since it can be mounted axially.

» The hubs can be equipped with the proven patented L-Loc clamping system.

With L-Loc, the coupling hub can be fit to splined shafts absolutely free of movement to eliminate fretting.

» The hubs can be modified in form and length as required.

» Various series for standardised SAE-flywheels and non-standard flywheels.

» Low priced and normally available from stock.

LK torsional couplings are usable with all engine-driven hydrostatic applications in the low to mid power range. They are maintenance-free and are characterized by low weight, high torsional stiffness and long service life. Their performance spectrum includes all ranges from 125 to 6,000 Nm. The shape and length of the hubs are modifiable, different flange positions are possible. Various series are available for standardized SAE flywheels and non-standardized flywheels.

See pages 27 to 29 of the torsional couplings catalogue for details:

www.jbj.co.uk/e-publications/Torsional-couplings-from-jbj_Techniques_Limited/29/index.html

LM Torsional Coupling System

The LM torsional couplings are made especially for diesel engine drives. In particular, the LM couplings are highly elastic torsionally, allowing the engine to drive a relatively small inertia load safely from damaging torsional resonance over a wide speed range from low idle RPM to full engine speed. They accomplish this task by shifting the critical speeds far enough below the idle speed to allow full use of the entire working speed range of the engine without limitation. In essence these sophisticated couplings effect an attenuated level of stress throughout the whole drive train by reducing vibratory torque to a very low level.

The shape of the elastomeric element distributes operating stresses equally over its working section, allowing for a large angle of twist, 6° to 12° at nominal torque load depending on size, while minimizing stress. This feature places the LM coupling amongst the highest torsional elasticities of all couplings available on the market. At the thick centre portion near the hub, as well as the cogs, stresses are further reduced to a very low level, providing a very reliable and robust drive.

See pages 32 to 43 for further LM torsional coupling information

https://www.jbj.co.uk/e-publications/Torsional-couplings-from-jbj_Techniques_Limited/33/index.html