Complies with the current ATEX Directive for:

II 2G Ex h IIC T6 ... T2 Gb X

II 2D Ex h IIIC T85 °C ... 250 °C Db X

I M2 Ex h Mb X

Below you will find:

»

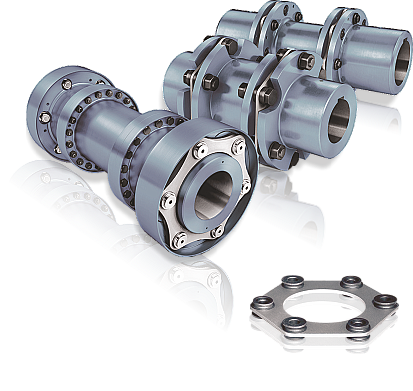

Attributes of the disc coupling range.

»

Steps in selecting a disc coupling.

»

Application service factors selection data.

»

Technical specification catalogue.

»

Fill in work sheet for help to specify coupling.

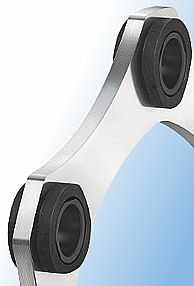

Backlash-free, torsionally rigid, all-steel, multi-plate couplings. Torque capacity up to 2,000,000 Nm.