In today's fast-paced industrial landscape, maximising efficiency is not just a goal but a necessity for businesses to thrive. One vital component in achieving operational excellence is the use of mechanical power transmission solutions. These solutions play an important role in powering various machinery and systems, and when used correctly, they can significantly enhance productivity, reduce downtime, and ultimately improve your bottom line. Today, we'll explore how our mechanical power transmission specialists can help you unlock efficiency and transform your operations.

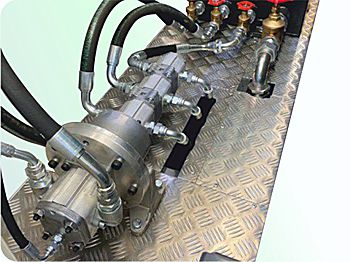

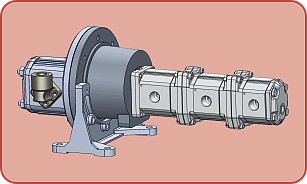

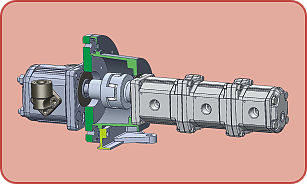

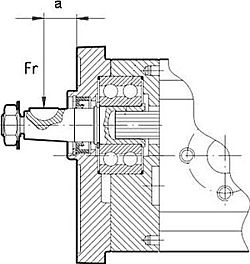

Mechanical power transmission refers to the mechanisms that transmit power from a source to a destination within a machine or system. It encompasses a wide range of components, including gears, belts, chains, couplings, bearings, and more. These components are the unsung heroes behind the seamless operation of your machinery, ensuring the smooth transfer of power from motors to critical processes.

Downtime is the enemy of productivity. Our experts focus on enhancing the reliability and durability of your power transmission systems.This means fewer unexpected breakdowns and maintenance-related interruptions,allowing your operations to run seamlessly. With our solutions, you can extend the lifespan of your equipment and reduce the total cost of ownership.

Precision engineering lies at the core of our mechanical power transmission solutions. Our specialists meticulously select and configure components to optimise power transfer while reducing energy loss. By using state-of-the-art design techniques and materials, we ensure that your machinery operates at its highest efficiency levels, translating to reduced energy consumption and increased cost savings.

One size does not fit all when it comes to mechanical power transmission. Each industry and application have unique requirements, and that's where our specialists excel. We understand that off-the-shelf solutions may not always suffice. We work closely with you to assess your specific needs and design tailored transmission systems that align with your operational goals.

Safety is paramount in any industrial setting. Our mechanical power transmission solutions not only boost efficiency but also ad here to the highest safety standards and regulations. We focus on the well-being of your workforce by implementing safety features and practices that minimise risks associated with power transmission equipment.

In an era where sustainability is a global priority, our specialists offer eco-friendly transmission solutions. By reducing energy wastage and ensuring optimal performance, we contribute to your company's efforts in achieving sustainability goals and reducing its carbon footprint.

Our commitment goes far beyond the initial installation of your system. We are dedicated to offering ongoing support, regular maintenance,and periodic assessments, ensuring that your operations continue to reap the benefits of enhanced efficiency over the long term.

Product Specification Excellence - When you choose JBJ Techniques Limited, you gain access to our unparalleled expertise in product specification. Our team of highly skilled design engineers is ready to assist you in the design process, regardless of complexity. Whether your project requires standard components or bespoke solutions tailored to your unique needs, our specialists will meticulously specify each product or combination of products to exact standards, ensuring they are not only fit for purpose but also safe to run as part of your mechanical power transmission system.

Prompt Product Supply - Time is often of the essence in the industrial world. At JBJ Techniques Limited, we understand the urgency of your requirements. With extensive stocks readily available, we offer next-day delivery on many items. This means you can count on us for prompt product supply, reducing downtime and keeping your operations running smoothly.

In-House Machine Shop - Our commitment to delivering top-notch mechanical power transmission solutions extends to our in-house machine shop. Here, we offer full machining services to support both standard and bespoke designs. Whether you need modifications, customisations, or entirely unique components, our machine shop is equipped with the latest technology and staffed by skilled professionals ready to bring your vision to life.

So, when you turn to our team at JBJ Techniques Limited, you can have a partnership that is built on trust, expertise, and unwavering commitment. We don't just offer mechanical power transmission solutions; we offer the promise of enduring success for your operations.

Our dedication to individualised product specification,prompt supply, and in-house machining services ensures that we are your comprehensive partner for all your power transmission needs. From design assistance to ongoing support and maintenance, we stand by your side, working together to achieve peak efficiency and long-term excellence in your mechanical power transmission systems.

Take a look at our

full product list to see what we offer, and if you’re interested in learning more about how our team can help you, get in touch via the

contact form today.