Windup and Backlash

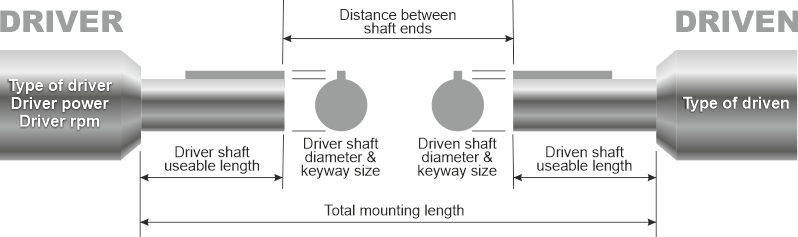

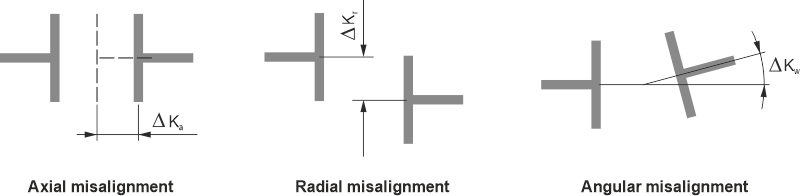

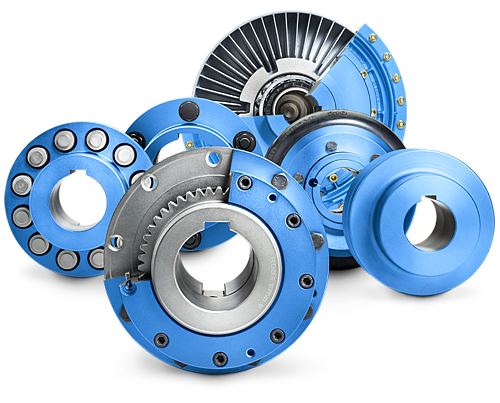

The functional requirement to interconnect rotating shafts across a wide range of machinery has driven the development of an equally broad spectrum of flexible coupling designs. At the lower end, this includes economical, lightweight couplings suited for shaft diameters as small as 4 to 5 mm. At the upper end are high-capacity, multi-element couplings engineered for heavy-duty applications with shaft diameters in the 150 to 500 mm range. Across this spectrum, the unifying design objective is the ability to accommodate angular, parallel, and axial misalignments while simultaneously satisfying application-specific demands for torsional rigidity, permissible backlash, and dynamic performance.

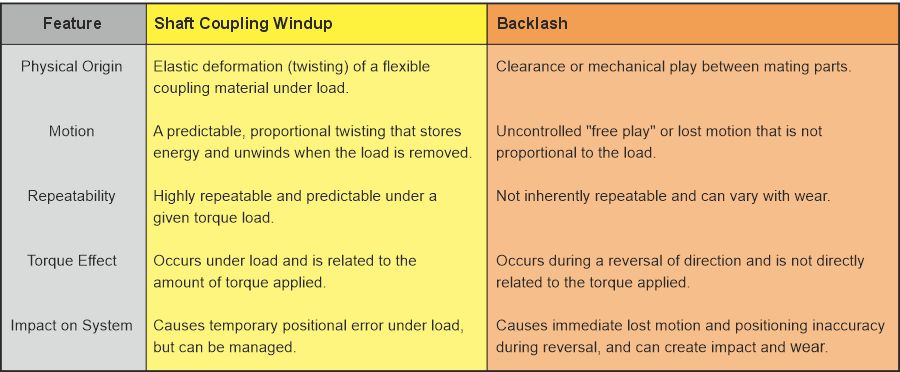

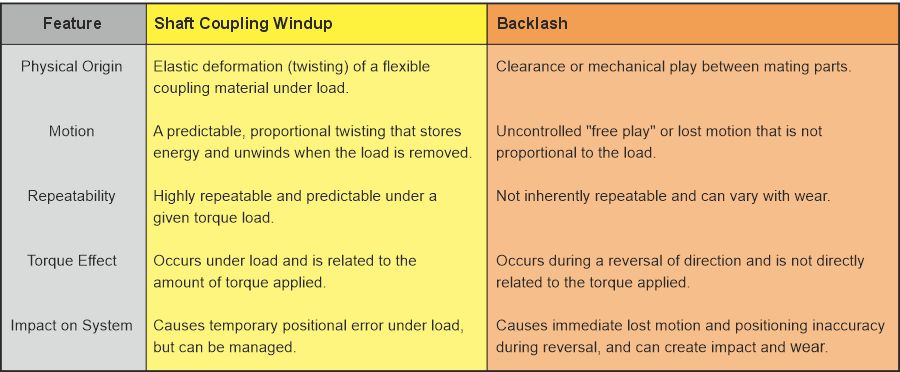

Shaft coupling windup and backlash are fundamentally different types of mechanical error, although both can cause inaccuracies in a rotational system. They are related in that they both cause lost motion, but they arise from different physical phenomena.

Key differences between Windup and Backlash summarized

Advantages of Couplings that Prevent Drive Windup

Couplings that prevent drive windup offer superior precision, repeatability, and system stability by eliminating unwanted rotational deflection between the driving and driven shafts. This prevention is critical for high-performance applications where any play or angular lag can cause significant errors or system damage.

What is drive windup?

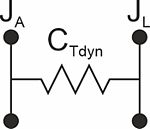

Drive windup, also known as torsional windup, occurs when a torque load causes a coupling to twist elastically like a spring. This causes a difference in the angular position between the motor and the load. While the coupling may return to its original position when the load is removed, this elastic deformation is unacceptable in many motion control applications.

Advantages of couplings that prevent windup.

Enhanced precision and positioning accuracy.

» Ensures exact motion: By eliminating the "give" of torsional windup, these couplings guarantee that the driven shaft's rotation perfectly matches the driving shaft's rotation.

» Improves repeatability: They ensure that a system will return to the exact same position every time, which is essential for robotics, CNC machines, and automated inspection systems, for example.

Increased system stability and performance

» Faster settling times: In applications involving rapid acceleration and deceleration, windup causes the system to oscillate before settling. Couplings with high torsional stiffness prevent this by ensuring a more immediate and stable response.

» Reduces overshoot: Torsional windup can cause a system to overshoot its target, which can be detrimental in sensitive applications. Couplings that prevent windup provide a more predictable and controlled movement.

Prolonged service life and reliability

» Reduces wear and stress: The elastic twisting of windup puts stress on the coupling and connected components like bearings and seals. By maintaining a more rigid connection, anti-windup couplings reduce this stress and extend the lifespan of your equipment.

» Minimizes backlash: Couplings that prevent windup are also designed to be backlash-free, meaning there is no lost motion or play when the direction of rotation is reversed. This prevents wear and protects against cumulative positioning errors.

Better for high-tech and dynamic applications

» Ideal for servo systems: High-gain servo systems are particularly susceptible to the performance degradation caused by windup. Zero-backlash, anti-windup couplings are a necessity for these systems to achieve their intended accuracy and responsiveness.

» Essential for high-speed use: In applications with high rotational speeds, even small amounts of windup can cause significant instability and vibration. Couplings with high torsional stiffness maintain a more balanced and stable drive, even at high RPMs.

Common couplings that prevent windup

Several types of couplings are designed to minimize or eliminate drive windup by maximizing torsional rigidity:

» Beam and helical couplings: These are machined from a single piece of material, and the cuts provide flexibility to accommodate misalignment while maintaining high torsional stiffness.

» Bellows couplings: Featuring a thin, flexible, metallic corrugated section, these couplings offer high torsional stiffness and precise torque transmission.

» Disc couplings: These use one or more flexible metal discs that allow for misalignment while transmitting torque with high torsional rigidity.

» Oldham couplings: Using a central disc between two hubs, these couplings transmit torque with zero backlash and are designed for high precision.

Advantages of Backlash Free Couplings

Backlash is the unwanted movement between coupling components which can compromise the performance of systems requiring exact motion control. Zero backlash couplings such as the Flender Bipex-S and the Trasco-ES spider couplings eliminate this issue by ensuring that torque is transmitted immediately and directly without any lag. This is achieved using an elastomeric ring available in various hardness levels, which acts as a buffer while maintaining rigidity under load.

Improved precision and accuracy

Exact positioning: By eliminating the lost motion inherent in couplings with backlash, these devices ensure that when a motor turns a specific amount, the driven shaft turns precisely the same amount. This is vital for accurate and repeatable positioning, especially in robotics, CNC machinery, for example.

No cumulative error: In systems with frequent starts, stops, and reversals, backlash can cause small errors to accumulate over time. Backlash-free couplings prevent these cumulative errors, ensuring consistent accuracy throughout operation.

Enhanced system performance and stability

Greater repeatability: The consistent, one-to-one transmission of motion enables predictable performance, which is crucial for manufacturing and inspection systems that require repeatable, reliable results.

Better motion control: Backlash-free couplings provide high torsional stiffness, meaning they do not twist under high torque loads. This results in a faster, more responsive system, which is essential for modern servo-driven applications and other dynamic systems.

Reduced vibration and shock: Certain backlash-free couplings, particularly elastomeric types, are designed to dampen vibrations and absorb mechanical shock loads. This reduces noise and extends the life of sensitive system components, such as bearings and actuators.

Increased longevity and reliability

Longer component life: By eliminating impact loads caused by "play” during changes in direction, backlash-free couplings reduce wear and tear on other mechanical components.

Reduced maintenance: Many all-steel disc-pack couplings are wear-free and maintenance-free, offering a long service life when properly installed.

Wider application versatility

Accommodation of misalignment: Many backlash-free couplings are also flexible, accommodating axial, radial, and angular shaft misalignment. Different types, such as Oldham or beam couplings, are optimized for different types of misalignment, allowing engineers to select the perfect fit for their application.

Electrical isolation: Elastomeric spiders in certain couplings can electrically isolate the two connected hubs, preventing the transfer of leakage currents that could damage sensitive electronic equipment.

High-speed operation: Many types, especially disc and bellows couplings, are balanced for use in high-speed applications without causing unwanted vibration.

Conclusion

Windup and backlash represent two distinct but equally important challenges in rotational drive systems. While windup arises from elastic deformation under torque and is generally predictable, backlash stems from clearance between mating components and often leads to inconsistent, cumulative errors. Both phenomena reduce precision, stability, and efficiency, especially in high-performance applications such as robotics, CNC machining, and servo-driven systems for instance.

Modern coupling technologies, particularly zero-backlash and high-torsional-stiffness designs offer effective solutions by minimizing lost motion, improving repeatability, and extending system lifespan.

Selecting the right coupling depends on balancing torsional rigidity, misalignment accommodation, and application-specific performance requirements. Ultimately, understanding and mitigating windup and backlash is critical to achieving reliable motion control, ensuring system accuracy, and optimizing long-term operational performance.

jbj Techniques have the technical expertise to assist you in the specification of the best coupling for your needs and extensive machine shop services, all in-house to enable prompt despatch of those more bespoke couplings, large or small in size and quantity.

If you need assistance with selecting the correct coupling for your application we are here to help. Contact jbj now: