S-Flex Couplings

The reformulated S-Flex Endurance™ is the longest lasting and best performing EPDM product available on the market.

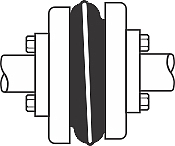

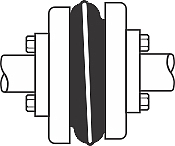

The simple design of the S–Flex (flexible sleeve) coupling ensures ease of assembly and reliable performance. No special tools are needed for installation or removal. The S–Flex couplings can be used in a wide variety of applications.

The new material also provides at least 30% increased torque rating and allows for product downsize in 50% of applications creating an average cost saving of 23 - 33% for sleeve element replacement.

Extensive testing performed by the R&D department compared the new and improved EPDM S-Flex Endurance sleeve element material to the previous design and competitor’s similar style couplings. Ultimately the new EPDM S-Flex Endurance material met or exceeded performance in every testing category. Note the performance improvements are for the EPDM material only. The Neoprene and Hytrel® types remain unchanged.

The S–Flex (flexible sleeve) coupling design is comprised of three parts. Two flanges with internal teeth engage an elastomeric flexible sleeve with external teeth. Each flange is attached to the respective shaft of the driver and driven and torque is transmitted across the flanges through the sleeve. Misalignment and torsional shock loads are absorbed by shear deflection in the sleeve.

The shear characteristic of the S–Flex coupling is very well suited to absorb impact loads. The S–Flex coupling from jbj Techniques offers combinations of flanges and sleeves which can be assembled to suit your specific application. Thirteen sizes are available with torque capabilities that range from 60 in-lbs (6.78 Nm) to 72,480 in-lbs (8189 Nm).The S–Flex flanges are offered in five models which are made from zinc die cast or cast iron. Sleeves are available in EPDM rubber, Neoprene, or Hytrel® to address a wide variety of application requirements.

S-Flex Coupling; protection from misalignment, shock, and vibration:

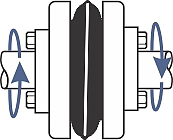

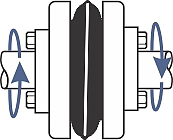

Parallel:

The S-Flex coupling accepts up to 1.5748 mm of parallel misalignment without wear. The flexible coupling sleeve minimizes the radial loads imposed on equipment bearings, a problem commonly associated with parallel misalignment.

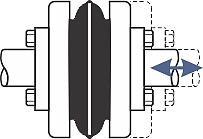

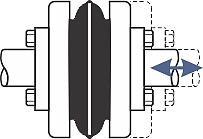

Axial:

The S-Flex couplings can be used in applications which require a limited amount of shaft end-float without transferring thrust loads to equipment bearings. Axial movement of approximately 3.175 mm accepted.

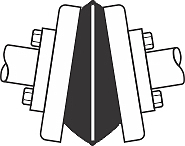

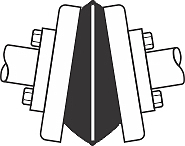

Angular:

The flexing action of the elastomeric sleeve and the locking feature of the mating teeth allows the S-Flex coupling to effectively handle angular misalignment up to 1°.

Torsional:

S-Flex couplings effectively dampen torsional shock and vibration to protect connected equipment. The EPDM and neoprene sleeves have torsional wind-up flexibility of 15° at their rated torque. Hytrel provides 7° wind-up.

Flange Types:

J Type — Zinc Die Cast and Cast Iron, Bore Range … 9.525 mm to 36.5 mm

S Type — Cast Iron, Bore Range … 12.7 mm to 139.7 mm

B Type — Cast Iron with bushing.

SC Type — Cast Iron Spacer.

T Type — Cast Iron with Taper-lock bushing.

Hubs for SC Type Spacer Coupling:

SCH Type — Powdered Metal or Cast Iron, Standard Length.

SCHS Type — Powdered Metal or Cast Iron, Short Length.

Sleeve Types:

JE (EPDM) 1–piece solid.

JES (EPDM) 1–piece split.

JN (Neoprene) 1–piece solid.

JNS (Neoprene) 1–piece split.

E (EPDM) 2–piece with retaining ring.

N (Neoprene) 2–piece with retaining ring.

H (Hytrel) 1–piece.

HS (Hytrel) 2–piece split.

Heading