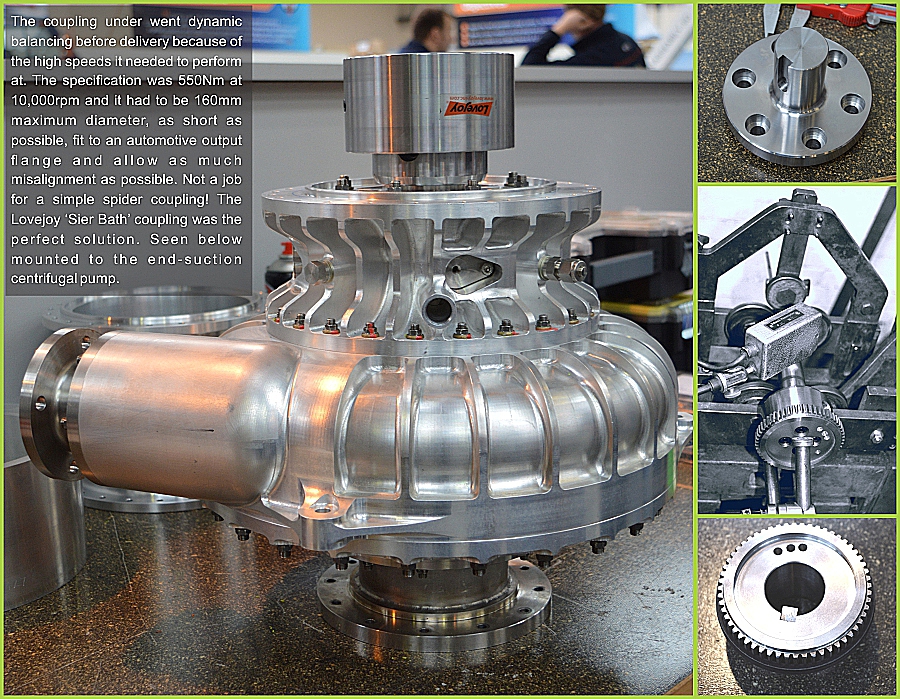

jbj Techniques’s proposed solution required a special drive shaft, which when connected to the output flange of an automotive gearbox enabled easy assembly of the Sier Bath Unit. 3D models were then supplied and approved by the

Bloodhound SSC team and after manufacture the complete assembly was dynamically balanced to ensure that the coupling operated without generating any additional forces.

The fuel pump is the pump for the rocket, effectively it's an end suction centrifugal pump driven by a Jaguar 'F' type V8 engine. It’s roll is to pump the oxidizing agent (hydrogen peroxide) into the rocket engine which contains the actual (solid) fuel (rubber). The other engine is a jet and does not require a separate pump.

The end-suction centrifugal pump is basically an impeller mounted within a volute housing, the impeller is mounted on a shaft supported on two bearings. One is mounted close behind the impeller with a pressurised double mechanical seal to prevent leakage. A bearing housing accommodates the length of the shaft and ensures a suitable gap between the bearings sufficient to support the rotating parts. This picture shows it standing on its suction inlet (picture above) flange with the outlet (discharge) pointing to the left and the coupling at the top mounted on the end of the shaft.