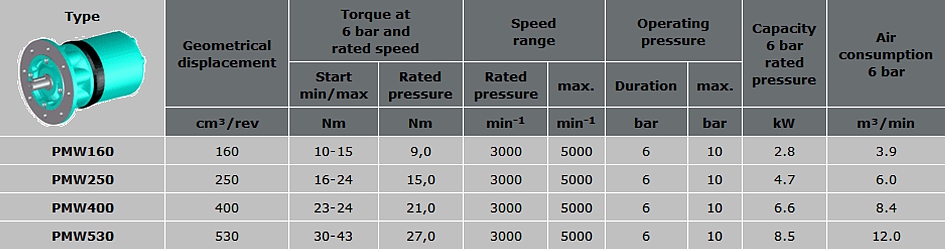

Capacity 2.8 - 8.5 kW» Particularly suited for operation in explosive environment.

» Solid construction garantees high operation security.

» Long life-time due hardened and grinded rotors.

» Good silencing due long exhaust ways.

» rpm-adjustment by easy throttle control.

» Direction change by way-valves with manual or remote control.

» Higher start-torque than torque at maximum power.

» Safe in damp atmosphere and extreme climatic conditions.

» With oiler for permanent operation and damp air.

» Additional silencers are available.

» Works with gas, air, nitrogen.

» Special construction for operation with un-oiled air Waterproofed.

» Time-unlimited overload also at stand still.

» Standardized flange and shaft dimensions compatible with electro-motors.

» IEC flange and shaft dimensions according DIN42677.

» Link to

application examples

.

» Link to

ordering code information.

» Link to a range of

accessories available for PMW series and DMO series pneumatic motors.