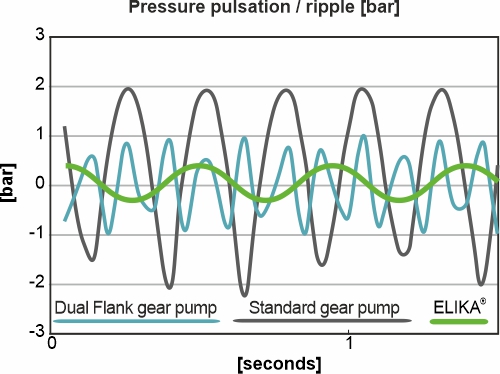

Q1: What sets ELIKA apart from traditional external gear pumps?A: ELIKA employs a helical gear tooth profile that ensures continuous engagement, lowering pressure ripple and vibration. Its patented axial compensation system minimizes internal leakage, resulting in higher volumetric efficiency and longer life compared to straight-tooth gear pumps.

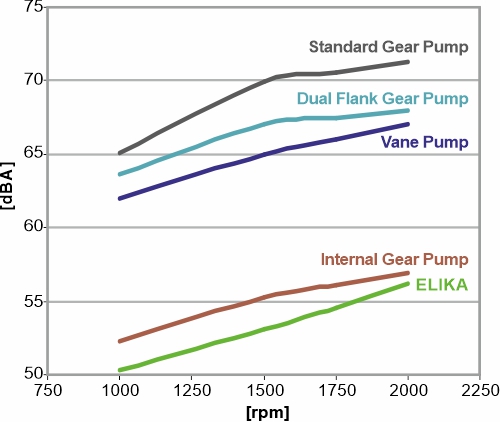

Q2: How does ELIKA achieve significant noise reduction?A: By spreading the load across the helical tooth surface, ELIKA reduces vibration and high-frequency excitation at the source. This translates into noise reductions of up to 20 dBA, a critical advantage in industries such as marine, transport, and food & beverage, where noise control is both a safety and comfort factor.

Q3: What are the pressure and speed capabilities of the ELIKA series?A: The pumps operate at continuous pressures up to 300 bar (310 bar peak) and maintain efficiency across wide speed ranges, making them suitable for high-demand environments such as offshore oil rigs, wind turbine yaw control, or motorsport actuation systems.

Q4: How does the pump maintain efficiency under varying operating conditions?A: ELIKA incorporates a patented dynamic compensation system that balances axial forces and reduces leakage. As a result, the pump delivers >90% volumetric efficiency even at low speeds, conserving energy and ensuring reliable operation in renewables, power generation, and environmental handling equipment.

Q5: What displacement and flow options are available?A:

» ELIKA1P: 2.1 to 8.1 cm³/rev.

» ELIKA2: 7 to 35 cm³/rev.

» ELIKA3: 20.4 to 87.1 cm³/rev.

» ELIKA4: 86.5 to 199.8 cm³/rev.

This range makes ELIKA equally suitable for precision dosing in food processing or heavy-duty lifting in marine and materials handling.

Q6: Can ELIKA be integrated into multi-pump systems?A: Yes. ELIKA is compatible with a wide range of gear pump families (for example ALP2/GHP2) and can be configured in tandem or multiple combinations, with both clockwise and counterclockwise rotation available. This allows system designers to create complex hydraulic circuits for applications such as power generation skids, offshore platforms, or mobile construction machinery.

Q7: What makes ELIKA suitable for noise-sensitive or precision-critical applications?A: The low-pressure ripple and reduced acoustic signature improve system stability, protect sensitive actuators, and reduce cavitation risks. This makes ELIKA ideal for motorsport, medical, renewable energy, and food processing, where precision and quiet operation are essential.

Q8: How does ELIKA contribute to energy savings and sustainability?A: High efficiency across the entire operating range results in reduced energy consumption, lower fluid temperatures, and extended service intervals. These benefits directly support sustainability goals in renewables, transport, and environmentally sensitive industries.

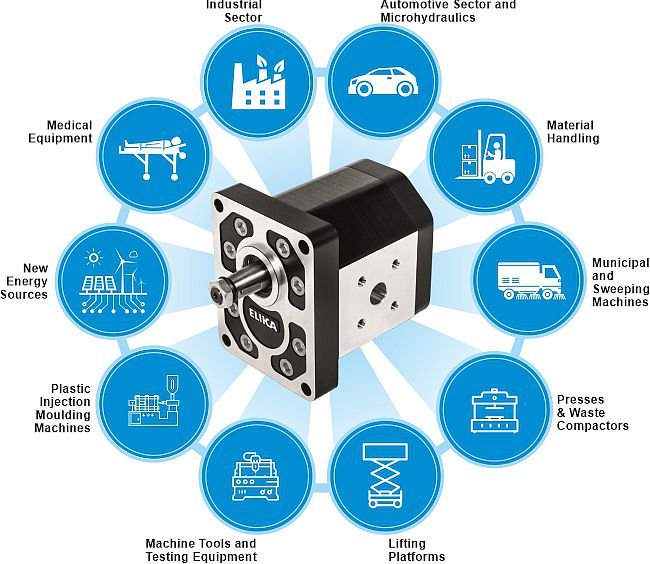

Q9: What industries benefit most from ELIKA technology?A:

» Power Generation: Reliable hydraulics for turbines, cooling, and auxiliary drives.

» Oil & Gas: High-pressure reliability for offshore and subsea systems.

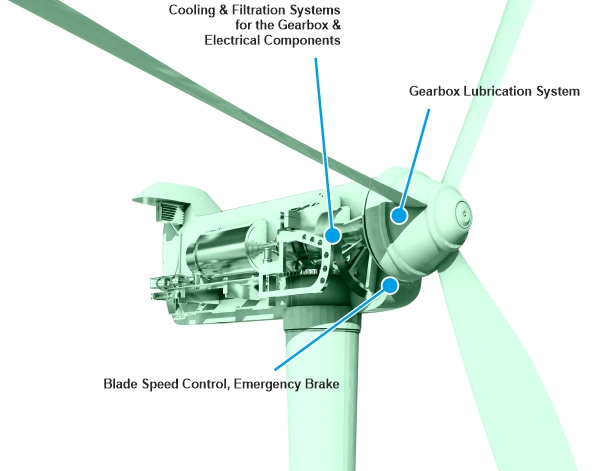

» Renewables: Silent, efficient hydraulics for wind, solar tracking, and hydro.

» Marine: Comfort and compliance through low-noise operation.

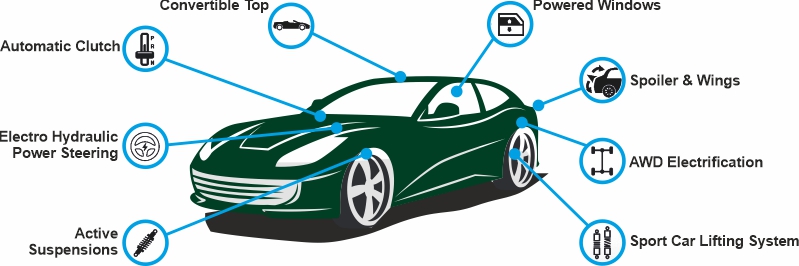

» Motorsport: High-speed, compact pumps for precise actuation.

» Food & Beverage: Quiet, hygienic dosing and processing applications.

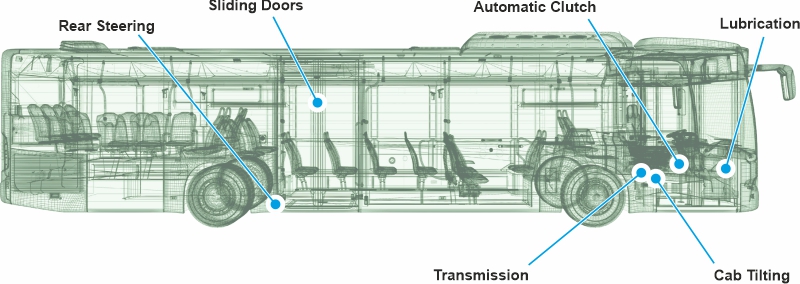

» Transport: Low-noise auxiliaries for EVs and hybrid systems.

» Environmental & Materials Handling: Efficient, sustainable lifting and recycling systems.

Q10: What makes ELIKA a future-ready solution?A: With its broad displacement range, high-pressure rating, energy-efficient design, and compatibility with multiple pump families, ELIKA is a versatile platform that supports both industrial and mobile hydraulic applications, making it a truly future-ready solution for the next generation of hydraulic systems.

ConclusionELIKA represents a breakthrough in hydraulic pump technology, offering unmatched noise reduction, efficiency, and versatility. Whether powering offshore oil rigs, enabling silent operation in electric vehicles, or improving energy efficiency in renewable energy systems, ELIKA delivers a proven solution for industries seeking to optimize performance while meeting modern demands for sustainability, safety, and operator comfort.

ELIKA®, Zero to 160 mph in 10 Seconds! A Rolls Royce 1978 Viper 535 Jet Engine, a VW and an after burner:

https://www.jbj.co.uk/marzocchi/0-to-160-mph-in-10-seconds