Hydraulic gear motors convert hydraulic pressure and flow into torque and angular displacement, rotary mechanical power, applied to a load via the shaft. Hydraulic fluid is moved into the motor causing the matched gear set to rotate. One of the gears is connected to the motor output shaft so producing the rotary mechanical power.

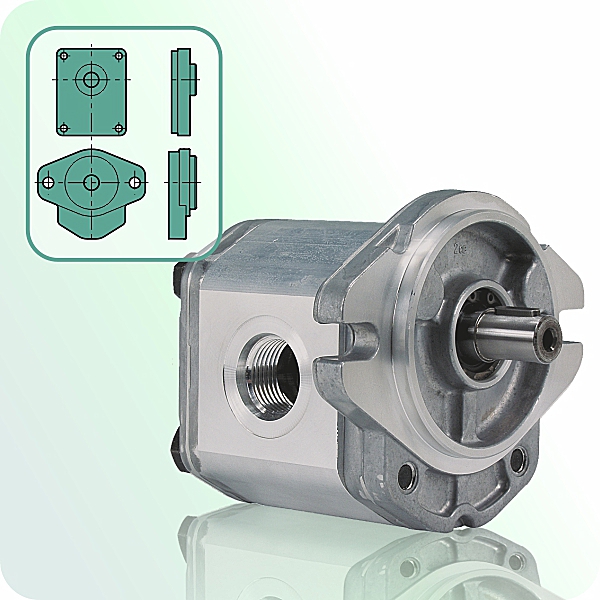

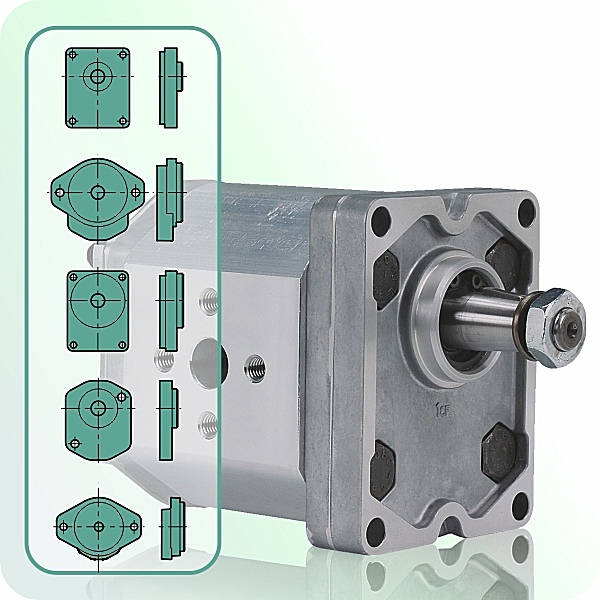

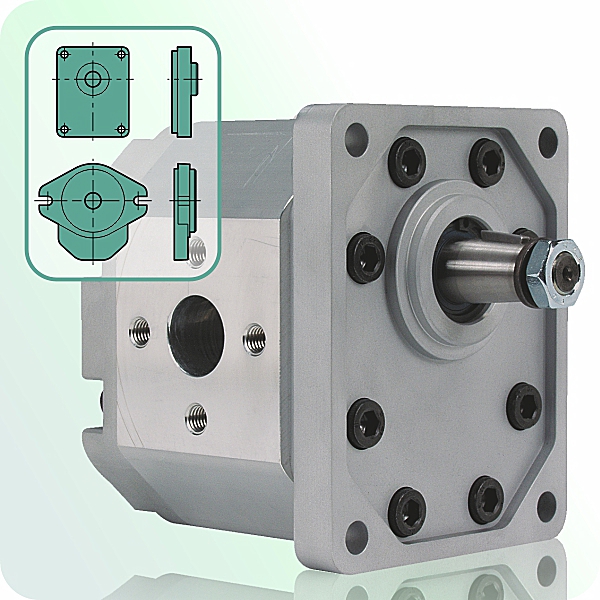

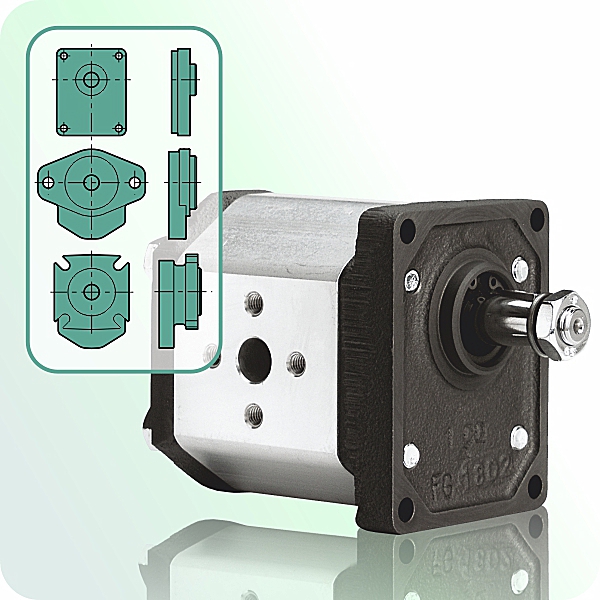

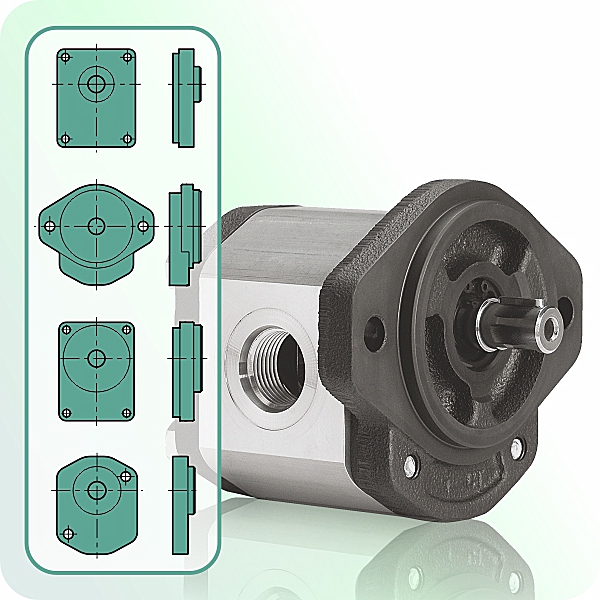

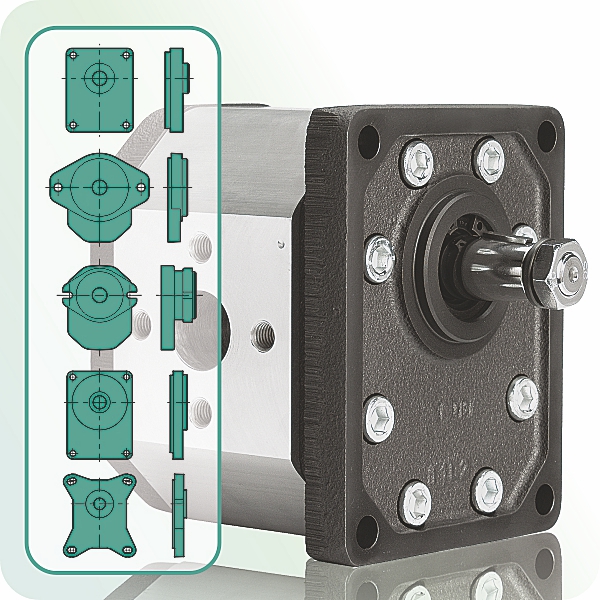

Hydraulic gear motors can be supplied in single or bi-rotational formats and units are available with a comprehensive range of mounting flange and shaft options including specific designs to accommodate high radial loads.

A complete range of integrated relief valves and anti-cavitation valves to suit a wide range of applications are available as standard.

A variety of materials used within the construction process ensure suitability for a wide range of fluids and environments.

Now including the new range of cast iron hydraulic gear motors for applications requiring high pressures, optimal performance and endurance.

A special shaft seal to allow hydraulic gear motors to bear extreme over-pressures without damage or failure.