BASIC HEAT EXCHANGE

Heat; the energy an object has because of the movement of its atoms and molecules.

Waste heat, not a nice term in today’s climate, is unfortunately a fact of life in industry and will necessitate removal or to better describe it, transfer from one object where it is undesirable to another where it is desirable, or at least will not cause damage. Good machinery design will minimise the transfer of energy to heat however mechanical equipment will invariably contain devices that generate heat due to friction of some sort. Consider a gearbox, the bearings will have rolling friction, the gears will have sliding friction, and the lubricating oil will be subject to constant movement, shearing and high pressures, the oil as well as lubricating the bearings and gears will also readily absorb the heat these components generate by nature of its contact at the various points of friction, which is handy.

Heat transfer; the process of thermal energy moving from one location to another.

Heat transfers from one object to another by conduction, convection and radiation, or by a combination of any of these. Worth noting is the greater the temperature differential (∆ ‘T’) the greater the rate of transfer.

Different substances will conduct heat to a greater of lesser extent, cast iron is a good heat conductor, wood is not. Oil is also good which is very useful for cooling applications.

As an example a gearbox running in a steady loaded state generates heat internally by the processes as described above. This heat is readily conducted into the oil, which in turn conducts the heat to the inner surfaces of the gearbox case. The material of the gearbox case conducts the heat to the outer surfaces of the gearbox where it is radiated into the surrounding air. The hot air will be replaced by cool air due to convection. Providing the combination of these heat transfer processes, components to oil - to surface - to surface - to air, results in cooling the gearbox oil sufficiently to maintain an acceptable steady state working temperature, all is fine.

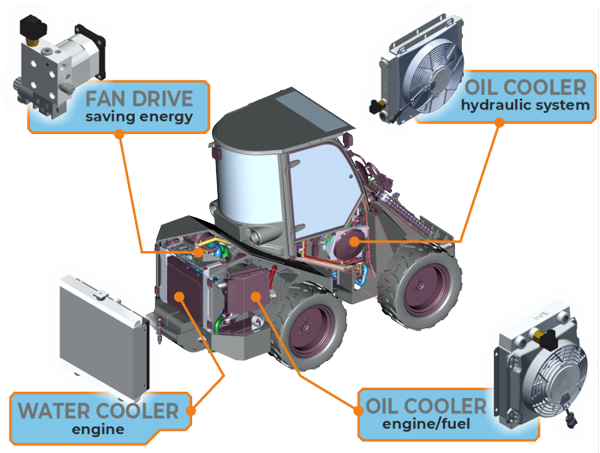

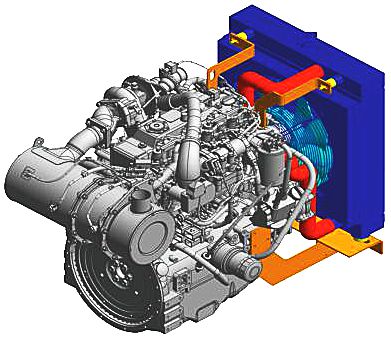

What if the heat input to the oil is greater than the capability of the combination of transfer processes to maintain an acceptable oil temperature? In this example the causes could be due to high mechanical strength of the gearbox resulting in high input power or a compact unit with a small outer surface area or thick case sections for instance. The resulting situation is a gearbox oil temperature that will continue to increase until it becomes ineffective resulting in damage to the gearbox. This is when the option to add an external cooling system must be considered.

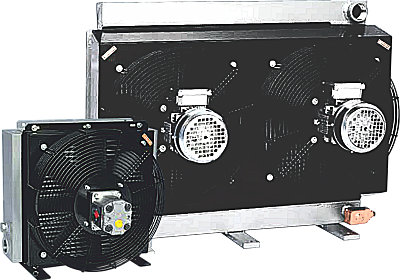

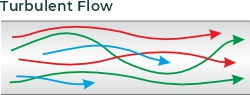

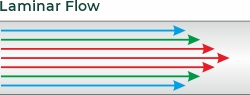

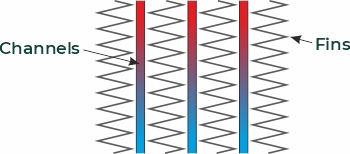

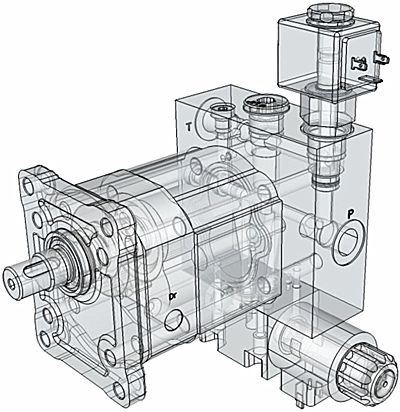

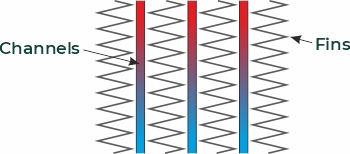

As mentioned, oil is a good conductor of heat plus it can also be pumped. Therefore the oil can be pumped out of the gearbox and into a heat exchanger. In this example the heat exchanger will be oil to air where the oil is passed through channels and air is blown over these channels by a fan. Air-blast cooler matrices are typically manufactured from aluminium which is a very good conductor of heat. The sections are thin which also allows heat to transfer more readily. In order to maximise the heat transfer the oil passageways have turbulators added to the inside surfaces in order to turbulate or stir the oil, known as turbulent flow. This will cause much of the hot oil to contact the sides of the channels and give a better heat transfer rate over the length of the channel. Without these turbulators the oil will pass through in laminar flow where the outside of the oil column will give up its heat leaving a central core at a higher temperature which in turn will result in less overall heat transfer.

On the air side of the channels thin fins are added. This has the effect of increasing the surface area subject to the passage of cooling air so the oil conducts its heat into the channels. The channels conduct their heat into the fins, the fins radiate their heat load into the air, the cooler fan speeds up the convection process so allows more heat to be washed away into the air. The cooled oil now returns to the gearbox where the cycle repeats forming a continuous conveyer belt of heat removal.

With our experience in cooling systems jbj can help in correctly sizing a heat exchanger, oil to air as described or fluid to fluid, for your application. We can look at machine system power input figures, oil flow rates, temperature differentials, required temperatures, heat loads, etc. and provide a solution for the removal of waste heat, or the transfer of heat from a heat source to equipment that requires the addition of heat. After all the process does work in the same way in reverse!