A helpful feature of the

MMC Series electromagnetic clutches designed for use in extreme conditions like those seen on lobster / shrimp / fishing boats is the "limp home feature".

The clutch is used to engage and disengage the

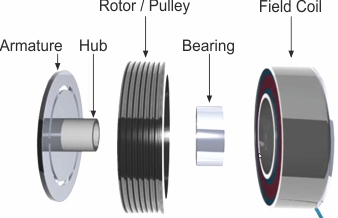

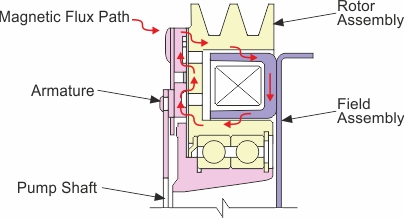

hydraulic pumps that lower or raise the nets or traps when hauling in the catch. While the clutch is a highly reliable component when applied properly, there are still times when things can go wrong, or the clutch just simply wears out. If the clutch will not engage or cannot drive the load, the MMC electromagnetic clutch features a “limp home” feature that allows the clutch to drive the pump without power. Two threaded holes in both the armature and rotor allow the operator to insert a bolt that draws and locks the two plates together. This provides a mechanical lockup to operate the equipment and continue fishing with a minimal loss of time and money.

All MMC clutches feature the limp home design and range in torque from 271 to 2033 Nm.

A variety of bore sizes and pulley options are available.

Most larger clutches operate via an inline drive and the clutch hub is fitted with a bolt pattern that matches common driveshaft couplings.

For technical data see

page 8 of technical specification catalogue

The patented Softstart Clutch Controller offers a simple solution to all of these issues!

» Mechanical Life: The

Softstart lessens forces to mechanical parts and improves the life of bolts, decks, brackets and other mechanical parts.

» Belt Life: Reduce wear and breakage for belts and improve the quality & reliability of the equipment.

» Engine Stall: The

Softstart eliminates engine stalling and RPM droop by utilizing closed loop RPM monitoring while engaging the electric clutch.

» Mechanical Jolt: Smooth engagement means less jolt to the equipment and customers.

» Engine Cost Savings: The

Softstart Clutch enables OEM's to reduce equipment engine size to save money.

Full information regarding the

Softstart controller found on

pages 12 and 13 of the technical specification catalogue

Industrial electromagnetic clutches, electromagnetic brakes and clutch brakes are used in many types of high speed, high cycle rate and long life machines including printers, packaging machines, food processing equipment, industrial mixers, and cash counting machines.

Magnetic particle, hysteresis slip clutches and magnetic particle, hysteresis slip brakes are used in many tension control systems to regulate the wind and unwind of fabric or carbon fiber or other materials during processing.

Also called particle clutch or particle brakes, they are used in new digital high resolution sign and photograph printers for professionals. Many designs are interchangeable with Warner Electric, DynCorp, KEB, Electroid, Lenze, Deltran, Intorq and Matrix.

Spring applied brakes, power off brakes, or spring set brakes (fail-safe brakes) are used in mobile, medical and robotic applications as well as used in radio telescopes. Also called servo motor brakes, they are also used to control electric wind generators, turbines and amusement rides from over speed conditions.

Industrial electric brakes are used in rail road crossing gates and parking lot/toll gates. These devices are also used in mailing machines, mail sorters and semiconductor processing applications.

Electric tooth clutches, electromagnetic tooth clutches and electric multiple disc clutches are used where high torque and small size are required. Customer applications include machine tool manufacturers, NC machines, lathes, milling machines and others. They are used by manufacturers of AC and DC electric motors including brake motors, brushless DC motors and servo motors.

Applications for these high reliability brakes include overhead doors, cranes, marine, construction equipment and brakes for super quiet use in stage and theatre can be supplied. Manual release levers or emergency release mechanisms can be available on many of these products if needed.