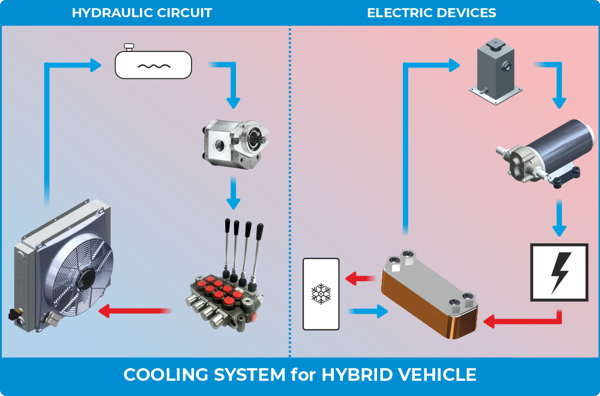

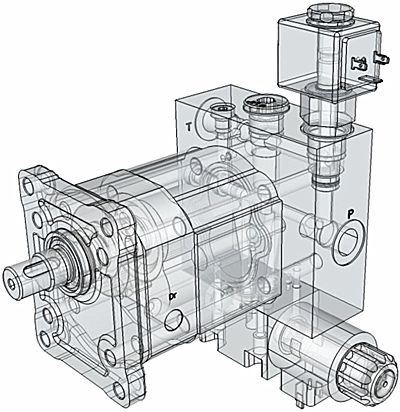

Is your electric vehicle battery running too hot?jbj Techniques has the solution.

We design and deliver complete autonomous cooling systems tailored to your EV battery requirements. Our systems integrate seamlessly with vehicle air conditioning circuits and feature energy-efficient fan drives that minimise power draw from the battery pack. From initial concept to fully packaged solutions - we’ve got you covered.

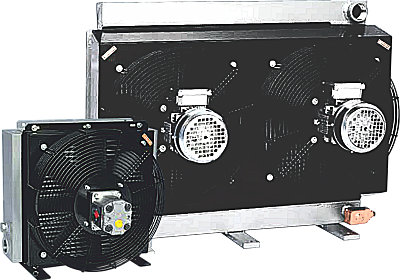

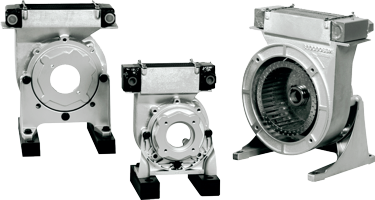

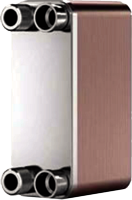

Overheating hydraulic system? jbj Techniques has the solution.

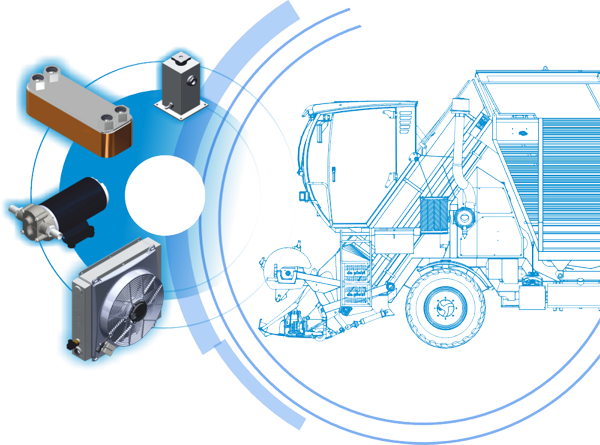

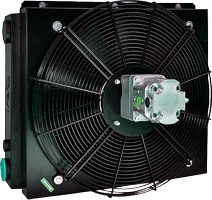

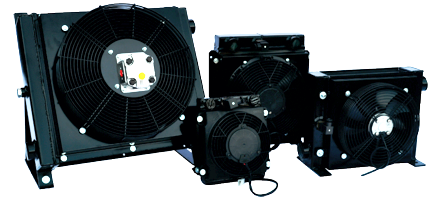

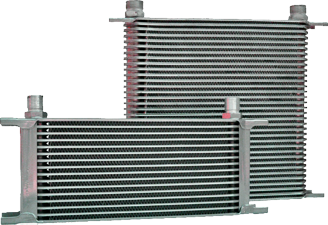

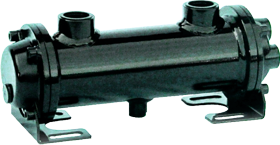

Choose from our extensive range of in-line or offline coolers to suit your specific application.

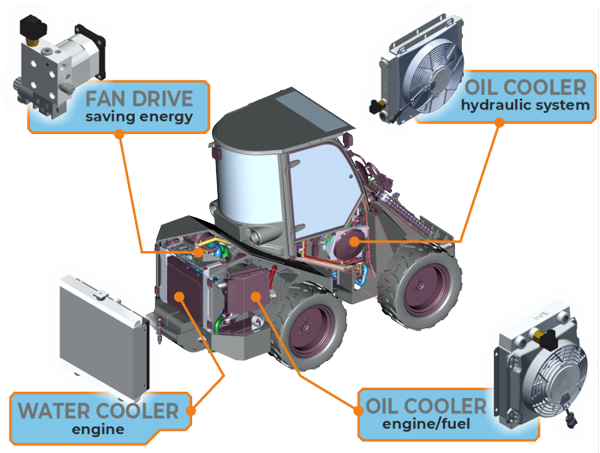

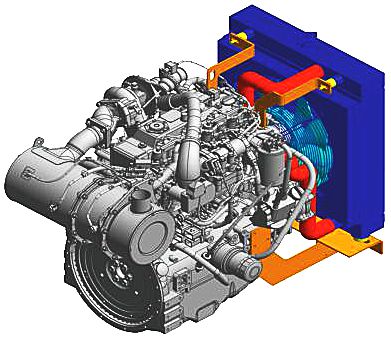

Need to cool a diesel or petrol engine, intercooler, or gearbox oil? jbj Techniques has the solution.

Whether you're a machine manufacturer seeking enhanced performance or need compact, multi-media cooling in a unique footprint - we provide efficient and reliable cooling components.